Sampling/Prototyping

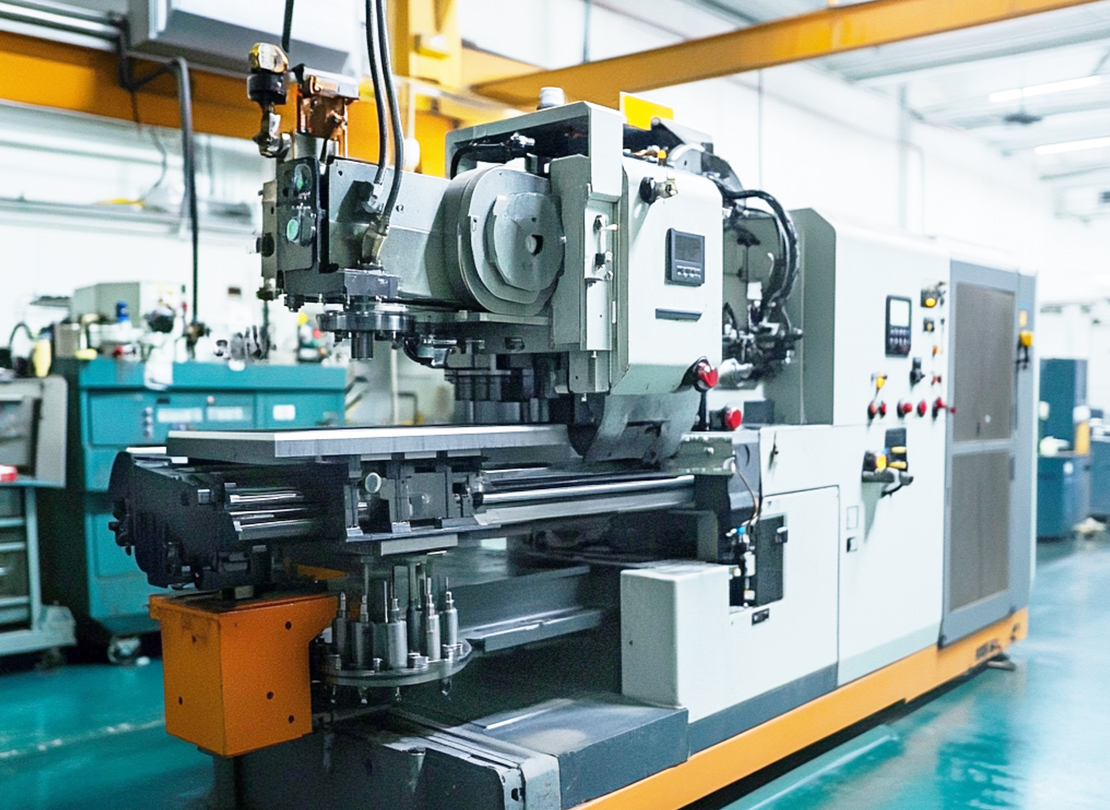

In terms of prototyping, our factory adopts advanced prototyping technologies, including 3D printing and precision cutting. These technologies enable us to quickly generate samples for practical testing. The prototyping process typically includes the following steps:

1. Sample Production:

Based on design drawings and CAD files, we produce initial samples. These samples can be made from plastic, metal, or other materials and are designed to showcase the product's appearance and functionality.

2. Functional Testing:

Once the samples are completed, we conduct a series of functional tests, such as durability testing, ease-of-use testing, and safety testing. These tests help identify potential issues and areas for improvement.

3. Client Validation:

After the samples pass internal testing, we send them to clients for real-world usage and collect their feedback. This phase is critical, as client input directly influences the final product.